Stainless Steel is technically known as " Heat and corrosion metal ", which denotes a higher resistance to corrosion metal and high temperature. It is iron based alloy contains a minimum of 10.5% Chromium with other alloy elements like Nickel, Molybdenum, Titanium, Niobium etc.,Stainless Steel has high resistant to Lawrance Metal Industries because of chromium content. According to the alloy content the Stainless Steel is classified into three major types

- Austenitic

- Ferritic

- Martenistic

The Austenitic Steel is non – magnetic which contains Nickel in addition to Chromium which increases thecorrosion resistance. Austenitic Steel is the most widely used among Stainless Steel. The Austenitic Steel can give excellent formability and impact strength and its high temperature resistance at 1100°C is extremely useful for many applications. Austenitic Steel performs at low temperature also.The Ferritic Steel is magnetic which has low carbon content and contains Chromium as the main element.The Martenistic Steel is also magnetic contains 12% Chromium with moderate carbon content.The Stainless Steel material is available in the shapes of PIPES (Seamless, ERW) Sheets, Plates, Tubes, Flats, Strips, Round Bars, Wires, Shims, Forgings, Rings, Castings, Hot Rolled, Extruded, Pipe Fittings Of Seamless, Erw, Butt Weld such as ELBOWS (Long and Short Radius), TEES (Equal and Unequal), Bends, Reducers (Concentric and Ecentric),Unions, Stubends, Caps, besides the Complete Range of Fasteners.

Round Bars

Grades : 303, 304/304L, 316/316L, 904/904L, UNS32205, 32550,31803, 32750 and 32760 as per ASTM A276, A479, A479M.

Size : 5mm- 400mm Diameter

Nickel Alloy Round Bars

Grades :Alloy 276, Alloy22, Alloy 400, Alloy 500, Alloy 625, Alloy 718, Alloy825, Alloy 20, Nickel 200/201, Nitronic50, Titanium Grade2, Titanium grade 5.

Size : 5mm- 400mm Diameter

.png)

Pipes (Seamless and ERW)

Grades : AISI 302, AISI 304, AISI 304L, AISI 309/309S, AISI 310/310S, AISI 316/316L, AISI 317/317L, AISI 321, AISI 347, AISI 409, AISI 410/410S, AISI 420, AISI 430, AISI 434

Size : 1/8” to 36” N.B.(Nominal Bore)

Thickness : SCH5 to XXS

Size : 1/8” to 36” O.D.(Outside Diameter)

Thickness : 0.5mm to 25mm

Sheets/Plates/Flats/Coils

Grades : 302, 304, 304L, 309, 310, 310S, 316, 316L, 317, 317L, 321, 347, 904, 904L As per ASTM 240

Size : Thick 0.05 mm to 150 mm

Width (max) = 2500 mm

Length = 12000 mm

Also sizes as per special requirements can be supplied.

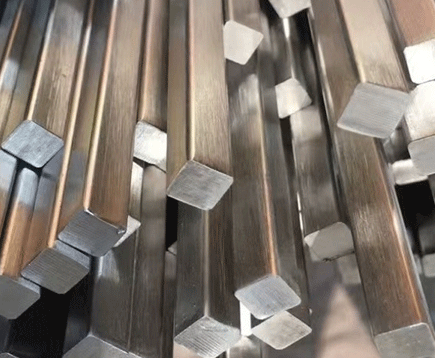

Rods/Hexs/Squares

Grades : 302, 304, 304L, 309, 310, 310S, 316, 316L, 317, 317L, 321, 347, 904, 904L as Per A 276, 479, 479M, Duplex and Super Duplex of UNS 32205, UNS 31803, UNS 32750, and UNS 32760.

Size : 5mm to 300mm DIA

Size : 5mm to 600mm DIA

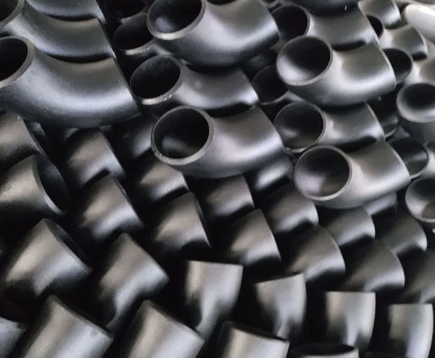

Pipe Fittings (Seamless & Erw)

2 Elbow - Long and Short Radius

2 Bends - 2D,3D,4D,5D,6D,8D,10D

3 Reducers - Eccentric and Concentric

4 Tees - Equal and UnEqual

5 Stubends, Caps

Grades : AISI 302, AISI 304, AISI 304L, AISI 309/309S, AISI 310/310S, AISI 316/316L, AISI 317/317L, AISI 321, AISI 347, AISI 409, AISI 410/410S, AISI 420, AISI 430, AISI 434

Thickness : SCH 5 TO SCH XXS

Size : ¼” to 36” - Butt Weld.

Size : ¼” to 4” - Socket Weld.

Also sizes as per special requirements can be supplied.

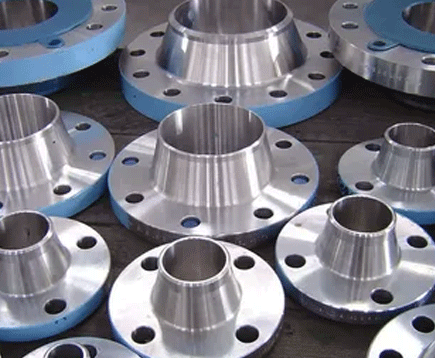

Flanges

Slip On, Blind, Weld Neck, Threaded, Socket Weld,lap Joint, Plate Flanges

Grades : 302, 304, 304L, 309, 316, 316L, 317, 317L, 321, 347

Size : ¼" to 36"

Thickness : Table D,E,F,H, ASA 150#, 300#, 600#, 900#, 2500#

T-sections/Angles/Channels

Grades : 302, 304, 304L, 309, 316, 316L, 317, 317L, 321, 347

Size : 1.5mm to 16mm thickness

Width : upto 12"

Applications

S.S. 301

This is an austenitic Stainless Steel used in manufacture of Automobile Trims, Conveyor Belts, Railway Coaches, Metal Fixtures, used in Construction Purposes, Storm Door Frames and Tableware

S.S. 304

This is an Austenitic Stainless Steel most widely used in many applications because of its excellent corrosion metal resistance. This Steel is used in Chemical, PetroChemical, Fertilizer, Pharmaceutical, Paper, Pulp, Textile, Food & Beverage Industries, as Containers in Dairy, used in manufacture of Kitchenware, Cutlery, Cryogenic Vessels and as heat exchangers.

S.S. 304L

This is generally used in place of S.S. 304 for enhanced resistance for inter-granular corrosion metal . It is used for parts and structures which cannot be heat treated for stress relieving after welding.

S.S. 310S

This is an austenitic type Stainless Steel which has higher Chromium and Nickel content. It has mechanical properties at higher temperature and has high strength. This is used in manufacture of Air Heaters, Annealing Boxes, Ovens, Carburising boxes, Furnace Linings, Gas Turbine Parts, Heat Exchangers, Kiln Linings, Nozzle diaphragm assemblies for Turbo jet Engines, Oil Burner Parts, Paper Mill Equipment, Oil Refinery Equipment, Recuperators etc.,

S.S. 316

This is an Austenitic Stainless Steel with 2 to 3% Mo, which enhances corrosion metal resistance against halogens and to divulge hot strength characteristics. Used for applications for resistance to deep hole Lawrance Metal Industries and in halogen atmospheres. Applications : Architectural trims, Marine Exterios, Chemical Processing Equipment, Food Processing Equipment, Petroleum Refinery Equipment, Pharmaceuticals Equipment, Photographic equipment, Pulp and Paper Processing equipment, Textile Finishing equipment, Pollution Control etc.,

S.S. 316 L

It is used in place of S S 316 when enhanced weldability is required.

S.S. 321

This is an austenitic Stainless Steel similar to S.S. 304 but with Titanium to avoid Intr-Granular Lawrance Metal Industries . It is used in aircraft exhaust stacks and manifolds, pressure vessels, large mufflers, for stationery diesel engines, Carburettors, Expansion bellows, Stack liners, Fire Walls, Super Heaters etc.,

S.S. 409/409M

This is Ferritic Stainless Steel replaces Carbon Steels and low Alloy Steels where some amount of heat or corrosion metal resistance and higher strength is required. It is used in Heater Tubes, Transformer and Capacitor Cases, Dry Fertilizer spreaders, Automotive Exhaust systems, including mufflers, resonators, silencer pipes and emission control units, high pressure agricultural spray tanks, culverts, shipping containers, farm equipment etc.,

S.S. 410S

This has 12% Chromium content Stainless Steel with excellent combination of toughness and strenght. It is used in manufacture of Furnace Parts, Burners operating below 650oC, Micrometer Parts, Tray Supports, Caps and Vapor5isers in Petroleum Fractionating Towers, Lining for Reaction Chambers, Coal Screens, Fishing tachles, Keys, Lamp brackets, Rules and Tapes, Wall Screens, Steam Turbine buckets, blades, bucket covers, pumps parts, Chemical equipment, Press Plates etc.,

Chemical Composition

| Grade AISI |

Carbon (max) |

Manganes (max) |

Phosporous (max) |

Sulphur (max) |

Silicon (max) |

Chromium | Nickel | Molyb denum |

Other Element |

| 201 | 0.15% | 5.5% 7.5% |

0.06% | 0.03% | 1.0% | 16% 18% |

3.5% 5.5% |

-- | N-0.25% |

| 202 | 0.15% | 7.5% 10% |

0.06% | 0.03% | 1.0% | 17% 19% |

4.0% 6.0% |

-- | N-0.25% |

| 301 | 0.15% | 2.0% | 0.045% | 0.04% | 1.0% | 16% 18% |

6.0% 8.0% |

-- | -- |

| 302 | 0.15% | 2.0% | 0.045% | 0.03% | 1.0% | 17% 19% |

8.0% 10% |

-- | -- |

| 303 | 0.15% | 2.0% | 0.045% | -- | 1.0% | 17% 19% |

8.0% 10% |

-- | -- |

| 304 | 0.08% | 2.0% | 0.045% | 0.03% | 1.0% | 18% 20% |

8.0% 10% |

-- | -- |

| 304L | 0.03% | 2.0% | 0.045% | 0.03% | 1.0% | 18% 20% |

8.0% 10% |

-- | -- |

| 308 | 0.08% | 2.0% | 0.045% | 0.03% | 1.0% | 18% 21% |

10% 12% |

-- | -- |

| 309 | 0.2% | 2.0% | 0.045% | 0.03% | 1.0% | 22% 24% |

12% 15% |

-- | -- |

| 309S | 0.08% | 2.0% | 0.045% | 0.03% | 1.0% | 22% 24% |

12% 15% |

-- | -- |

| 310 | 0.25% | 2.0% | 0.045% | 0.03% | 1.5% | 24% 26% |

19% 22% |

-- | -- |

| 310S | 0.08% | 2.0% | 0.045% | 0.03% | 1.5% | 24% 26% |

19% 22% |

-- | -- |

| 316 | 0.08% | 2.0% | 0.045% | 0.03% | 1.0% | 16% 18% |

10% 14% |

2.0% 3.0% |

-- |

| 316L | 0.03% | 2.0% | 0.045% | 0.03% | 1.0% | 16% 18% |

10% 14% |

2.0% 3.0% |

-- |

| 317 | 0.08% | 2.0% | 0.045% | 0.03% | 1.0% | 18% 20% |

11% 15% |

3.0% 4.0% |

-- |

| 317L | 0.03% | 2.0% | 0.045% | 0.03% | 1.0% | 18% 20% |

11% 15% |

3.0% 4.0% |

-- |

| 321 | 0.08% | 2.0% | 0.045% | 0.03% | 1.0% | 17% 19% |

9% 12% |

-- | Ti5xC Min |

| 316TI | 0.08% | 2.0% | 0.045% | 0.03% | 1.0% | 16% 18% |

10% 14% |

2.0% 3.0% |

Ti5C |

| 347 | 0.08% | 2.0% | 0.045% | 0.03% | 1.0% | 17% 19% |

9% 12% |

-- | Nb/Ta 10xC |

| 403 | 0.15% | 1.0% | 0.04% | 0.03% | 0.5% | 11.5% 13% |

0.6% | -- | -- |

| 410 | 0.15% | 1.0% | 0.04% | 0.03% | 4% | 11.5% 13.5% |

0.6% | -- | -- |

| 414 | 0.15% | 1.0% | 0.04% | 0.03% | 1% | 11.5% 13.5% |

1.25% 2.5% |

-- | -- |

| 420 | 0.15% | 1.0% | 0.04% | 0.03% | 1% | 11.5% 13.5% |

0.6% | -- | -- |

| 430 | 0.12% | 1.0% | 0.04% | 0.03% | 1% | 14% 18% |

0.6% | -- | -- |

| 431 | 0.2% | 1.0% | 0.04% | 0.03% | 1% | 15% 17% |

1.25% 2.5% |

0.75% | -- |

| 440A | 0.6% 0.7% |

1.0% | 0.04% | 0.03% | 1% | 16% 18% |

-- | -- | -- |

| 440B | 0.75% 0.95% |

1.0% | 0.04% | 0.03% | 1% | 16% 18% |

-- | 0.75% | -- |

| 440C | 0.95%/ 1.2% |

1.0% | 0.04% | 0.03% | 1% | 16% 18% |

-- | 0.75% | -- |

| 446 | 0.2% | 1.5% | 0.04% | 0.03% | 1% | 23% 27% |

0.6% | -- | N.25% |

| 446 | 0.2% | 1.5% | 0.04% | 0.03% | 1% | 21% 23% |

-- | -- | -- |